Common Knowledge about Tungsten Steel

Tungsten steel has a series of excellent properties such as high hardness, good wear resistance, high strength and durability, heat resistance, and corrosion resistance. Particularly, its high hardness and wear resistance remain unchanged even at 500℃, and it still maintains high hardness at 1000℃.

Tungsten steel, also known as hard alloy, is a sintered composite material composed of at least one metal carbide. The common components of tungsten steel include tungsten carbide, titanium carbide, and tantalum carbide. The grain size of the carbide components (or phases) is usually between 0.2 and 10 micrometers, and the carbide grains are bonded together by a metal binder. The binder is usually metal cobalt (Co), but for some special applications, nickel (Ni), iron (Fe), or other metals and alloys can also be used. The composition of a predetermined carbide and binder phase is called a “trade mark”.

The classification of tungsten steel is carried out according to ISO standards. This classification is based on the material type of the workpiece. The binder component mainly uses its strength and corrosion resistance.

The matrix of tungsten steel consists of two parts: one part is the hardening phase; the other part is the bonding metal. The bonding metal is usually a ferrous metal, and the commonly used ones are cobalt, nickel, and titanium. Thus, there are tungsten-cobalt alloys, tungsten-nickel alloys, and tungsten-titanium-cobalt alloys.

Steel containing tungsten, such as high-speed steel and some hot-forming tool steels, has a significant improvement in hardness and heat resistance due to the tungsten content in the steel, but the durability will sharply decrease.

The main application of tungsten is also hard alloy, which is also known as tungsten steel. Tungsten steel products are widely used.

The composition structure of tungsten steel sintering is to press the powder into a billet, then heat it to a certain temperature in a sintering furnace and maintain it for a certain period of time (holding time), and then cool it down to obtain the required functional tungsten steel material.

The tungsten steel sintering process can be divided into four basic periods:

- Removal of forming agent and pre-sintering period. During this period, the sintered body undergoes the following changes:

Removal of the forming agent. In the early stage of sintering, as the temperature increases, the forming agent gradually decomposes or vaporizes, and is removed from the sintered body. At the same time, the forming agent adds carbon to the sintered body to a certain extent, and the amount of carbon addition will change with the type, quantity of the forming agent, and the sintering technology.

The surface oxide of the powder is restored. At the sintering temperature, hydrogen can restore the oxides of cobalt and tungsten. If the forming agent is removed and sintered in a vacuum, the carbon-oxygen reaction is not intense. The contact stress between powder particles gradually disappears, the bonding metal powder begins to undergo recovery and recrystallization, and surface dispersion begins to occur, and the compressive strength of the pellet improves. - Solid-phase sintering period

At a temperature lower than the appearance of liquid phase, in addition to continuing the processes that occurred in the previous period, solid-phase reaction and dispersion intensify, plastic activity increases, and the sintered body shows obvious shrinkage. - Liquid-phase sintering period. When the sintered body shows a liquid phase, the shrinkage is completed quickly, and then a crystallization transformation occurs, forming the basic arrangement and structure of the alloy.

- Cooling period: During this period, the arrangement and phase composition of tungsten steel change under different cooling conditions, and this characteristic can be used to heat-treat tungsten steel to improve its physical and mechanical properties.

Application introduction: Tungsten steel belongs to hard alloy, also known as tungsten-titanium alloy. Its hardness can reach 89-95 HRA. Therefore, tungsten steel products (such as tungsten steel watches) have the characteristics of being difficult to be worn, being resistant to annealing, but being brittle.

The main components of hard alloy are tungsten carbide and cobalt, which account for 99% of all components, and 1% is other metals, so it is also called tungsten steel.

It is commonly used in high-precision mechanical processing, high-precision cutting tool materials, lathes, impact drills, drill heads for glass cutting, tile cutting tools, etc. It is resistant to annealing but brittle. It belongs to rare metals. Tungsten steel possesses a series of excellent properties such as high hardness, good wear resistance, high strength and durability, heat resistance, corrosion resistance, etc. Particularly, its high hardness and wear resistance remain unchanged even at a temperature of 500°C, and it still maintains high hardness at 1000°C. Cemented carbides are widely used as materials, such as cutting tools like drills, milling cutters, scrapers, drills, and boring tools, for cutting cast iron,有色金属, plastics, fibers, graphite, glass, stone, and common steel, and can also be used for cutting heat-resistant steel, stainless steel, high-manganese steel, and other difficult-to-machine materials. The cutting speed of new types of cemented carbides is hundreds of times that of carbon steel.

Tungsten steel can also be used to manufacture rock drilling tools, mining tools, drilling tools, measuring tools, wear-resistant parts, metal grinding tools, cylinder linings, precision bearings, nozzles, etc.

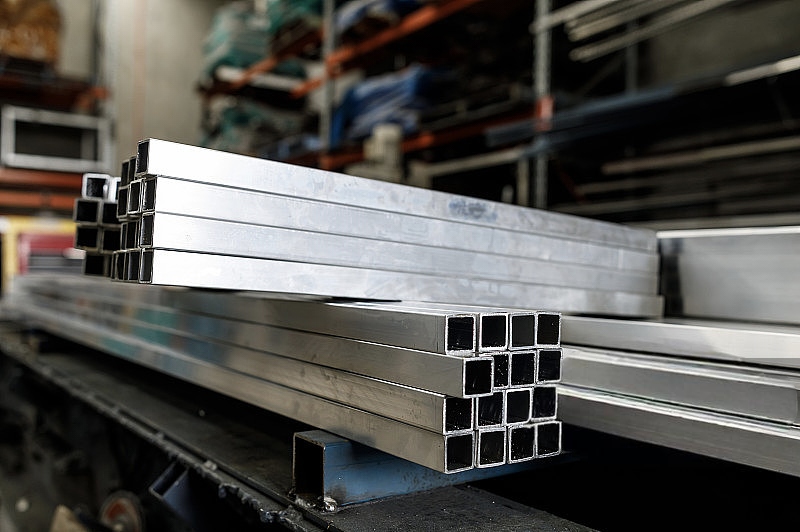

Tungsten steel, cemented carbide molds, plates, anvils, rollers, tools, and various tungsten steel and cemented carbide specifications and standards have a large inventory, with raw materials available for immediate supply.

Blade series: Tungsten steel products are widely used, such as tungsten steel round pieces used as special cutting tools for the electronics industry, typical representative products include cutting machine blades, tungsten steel V-CUT blades, fiber optic cutting blades.

Material series: Typical representative products of the tungsten steel series materials include: round bars, tungsten steel sheet materials, tungsten steel strips, etc.