Control of Spots and Stains on the Surface of Cold-Rolled Thin Sheets

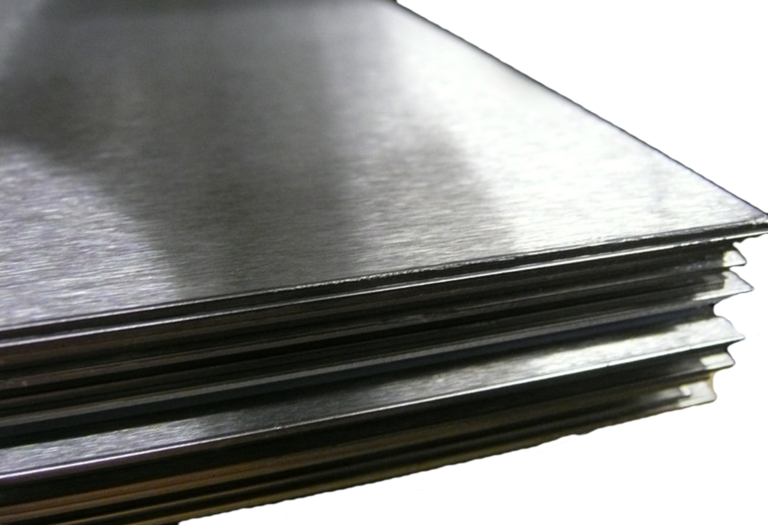

Among steel products, cold-rolled sheets have very strict requirements for surface quality. Surface defects are the most significant quality issues for cold-rolled sheets. Once surface defects occur in cold-rolled sheets, they will seriously affect the quality and performance of subsequent deep-processed products. For a period of time, the cold-rolled products of the First Steel Rolling Plant of Maanshan Iron & Steel Co., Ltd. were plagued by surface spot defects, which had a very adverse impact on the image of the products of the First Steel Rolling Plant and even Maanshan Iron & Steel in the market, and caused huge economic losses. From June 2011 to April 2012, the First Steel Rolling Plant’s cold-rolled products paid compensation for 21,417 tons due to quality issues, among which surface spot defect quality issues accounted for nearly one-third of the total quality issues, becoming an urgent problem to be solved.

The cold-rolled steel sheets of MaSteel have irregular spots, patches and streaks on their surfaces. The lighter ones are light yellow, while the more severe ones are brownish-yellow or red, and in the most serious cases, they are dark brown and the surfaces are rough. Maanshan Iron & Steel Co., Ltd. collaborated with the School of Science of Naval University of Engineering to analyze the factors causing the spots on the cold-rolled products. Firstly, they strengthened monitoring and management to eliminate the problem of small steel coils blocking the base when they were loaded into the furnace due to improper stacking and centering, which led to blackening of the steel coils after annealing and the inability to remove residual carbon on the surface. They also ruled out the possibility of surface rust caused by rain leakage in the warehouse or water droplets from air conditioners falling on the steel coils during crane movement, as well as uneven oil application in the oiling system. Then, they conducted in-depth analysis of the influencing factors.

They found that the majority of the spot defects occurred in the products of the flattening line, and reducing the output of the flattening line products and changing them to be produced by the finishing line could significantly reduce the occurrence of such defects. Among them, the flattening blow-off system and the flattening liquid system were closely related to the occurrence of surface spot defects.

- The influence of flattening liquid pH value on spots

Both acidic and alkaline liquids can corrode the surface of the steel sheet, easily forming fine point-like corrosion pits on the surface, which accumulate and oxidize to form spots. Experiments show that when the pH value is between 7 and 9, there is no correlation between the pH value and the occurrence of spots. Therefore, the pH value of the flattening liquid is set to be between 7 and 9. - The influence of flattening liquid concentration on spots

The flattening liquid comes into direct contact with the surface of the steel strip, and its purpose is to lubricate the rolling process of the steel coil. Experiments show that the concentration of the flattening liquid has a significant impact on spots. At a concentration of 2.4%, spots occur 100% of the time; at concentrations of 2.94%, 3.36%, 3.77%, and 4%, no spots occur. Based on the experimental results and cost considerations, the concentration of the flattening liquid is set to be greater than 2.4% and less than or equal to 4% as the operating standard. - The influence of dynamic blow-off pressure of flattening liquid on spots

The experimental results show that when the dynamic blow-off pressure of the flattening liquid is maintained at 5 kg or above, it has no effect on spots. Therefore, it is stipulated that the dynamic blow-off pressure of the flattening liquid must be maintained at 5 kg or above, and the machine will stop if it is below this standard value. - The influence of the temperature of the flattening liquid mixing tank on spots

The experimental results show that the temperature of the flattening liquid mixing tank is closely related to the occurrence of spots. When the temperature of the flattening liquid is above 50°C, the number of spotted coils is the least, and when it is below 30°C, the number of spotted coils is the most. Therefore, it is stipulated that the temperature of the flattening liquid mixing tank should be controlled above 50°C.

Based on the experimental and analytical results, MaSteel took corresponding measures, and the quality disputes caused by surface spots were significantly reduced, achieving excellent results, equivalent to an indirect increase of 79,200 yuan per month.