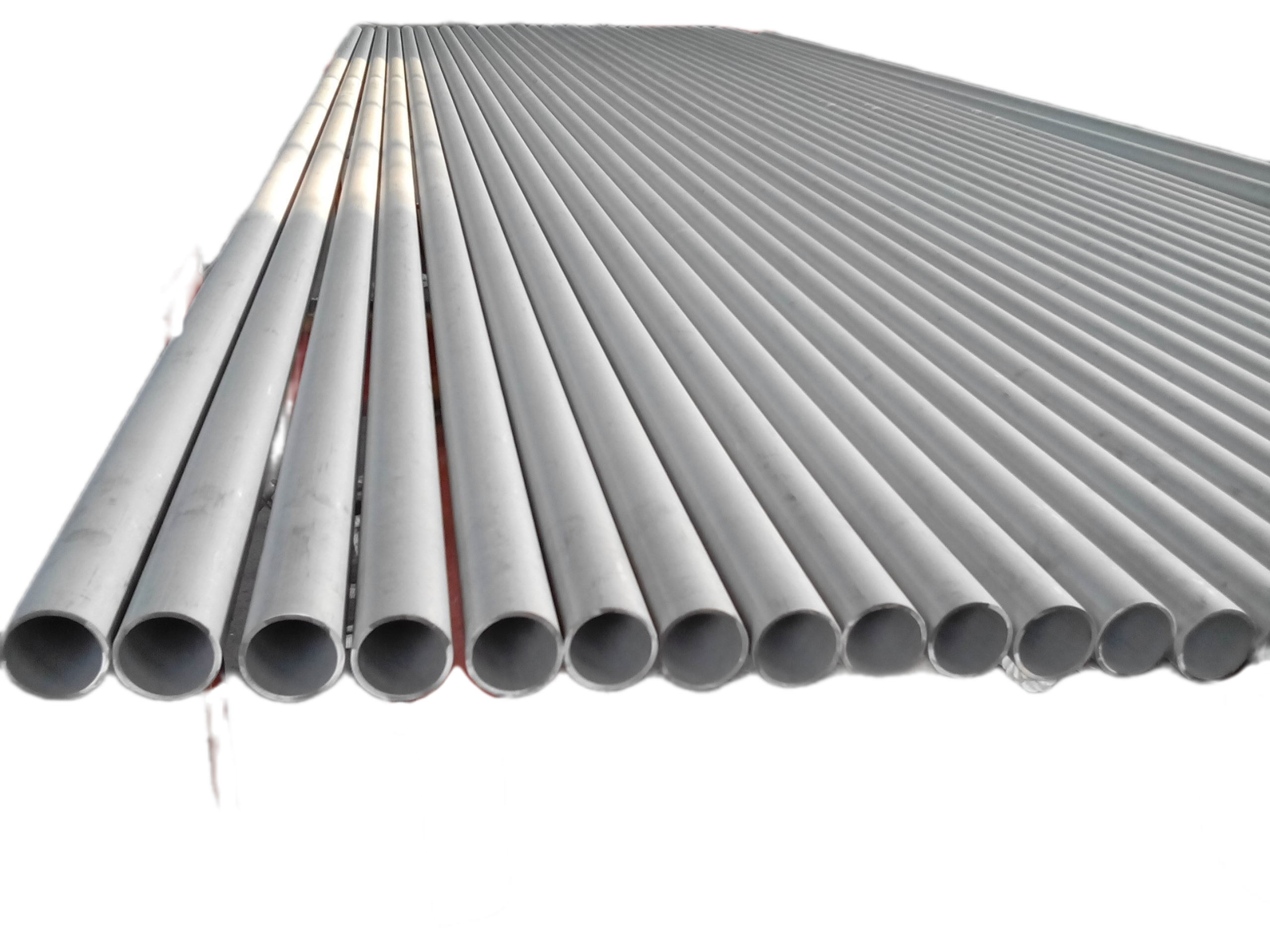

How is the repair of stainless steel welded pipes carried out?

There are also times when stainless steel welded pipes are of poor quality during production, which is a very normal phenomenon. We should promptly carry out repair work. The steps for repairing different problems are also different. Now let’s talk about how to operate the repair of stainless steel seamless pipes.

When steam leaks from the socket, it is necessary to know the type of filler for the socket in advance. If the leakage is caused by the loosening of the green lead (appearance: silver with dark blue) socket, before repairing, first clean the soil at the connection point thoroughly, and then use a chisel and hammer to tighten the lead socket. If there is a dent in the lead socket, add some lead strips and twist them into the channel until the lead socket stops leaking completely. If the joints of the concrete raw materials (such as powdered cementitious materials and inorganic admixtures) become loose, they should be removed and re-drilled. If the concrete socket becomes loose due to frequent vibration under the road surface, it can not only accelerate the repair rate but also improve the characteristics of the socket.

The leakage of steam through sand holes and gaps in stainless steel welded pipes can be repaired by drilling and tapping external threads. However, if steam leakage occurs on the pipe due to corrosion (such as rotting, fading, or corrosion), holes, gaps, or cracks (etc.), to quickly eliminate the safety accident. The “emergency repair hoop” method can be adopted to solve the problem. Place a sealing gasket made of ductile materials such as lead sheets or textile materials at the damaged point of the penetrating wall thickness, and then tighten and fix it with the construction steel hoop of the rear cover plate and U-shaped anchor bolts (composed of the top of the head and the screw of the extruder). This type of method can be applied to low-pressure stainless steel plate fuel pipelines. If it is used for high-pressure stainless steel plate fuel pipelines, only short-term temporary maintenance is required, and then the pressure should be reduced by welding and reinforcing thick steel plates.

If the gap of the water pipe is long, after drilling to stop the crack, two semi-circular sleeve specifications can be used. The gap between the sleeve specifications and the wall thickness can be sealed with the twist of the sealing packing, and then the sleeve specifications can be tightened and the anchor bolts tightened. The above is the repair instructions for operations such as air leakage at the socket of stainless steel welded pipes.