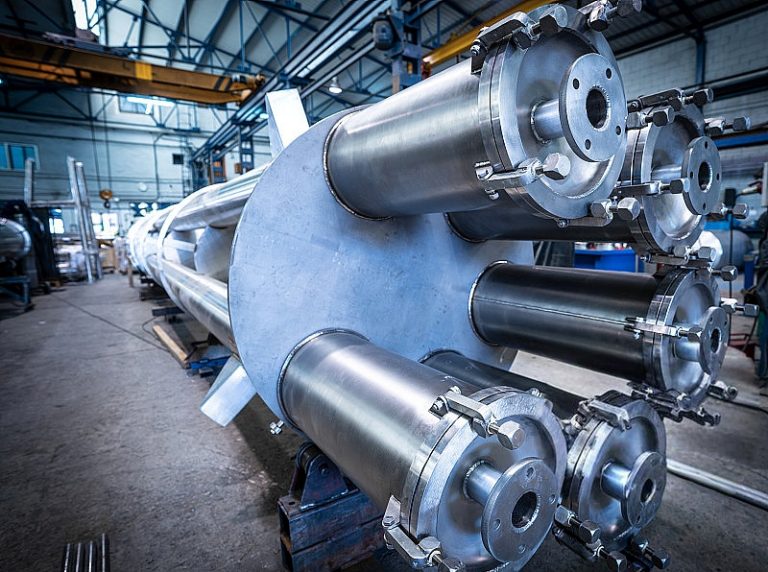

The application of stainless steel in the food industry

Due to the increasing application of stainless steel in the food industry, especially its excellent hygiene properties, corrosion resistance, and low maintenance costs, the demand for it has also grown. Stainless steel is widely used in food processing machinery, storage tanks, and kitchen catering equipment. The surface of the material after drilling does not affect…