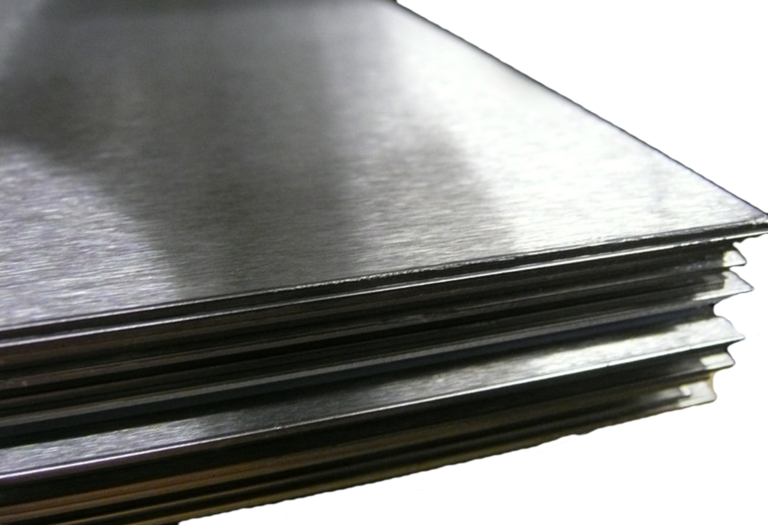

Overview of Stainless Steel Sheets

Stainless steel plates are generally the collective term for stainless steel plates and acid-resistant steel plates. They were introduced at the beginning of this century, and the development of stainless steel plates has laid an important material and technical foundation for the development of modern industry and scientific and technological progress. There are many types of stainless steel plates with different properties, and they have gradually formed several major categories during their development. According to the microstructure, they can be classified into four major categories: austenitic stainless steel plates, martensitic stainless steel plates (including precipitation-hardened stainless steel plates), ferritic stainless steel plates, and austenitic-ferritic duplex stainless steel plates. According to the main chemical components or characteristic elements in the steel plates, they can be classified into chromium stainless steel plates, chromium-nickel stainless steel plates, chromium-nickel-molybdenum stainless steel plates, low-carbon stainless steel plates, high-molybdenum stainless steel plates, and high-purity stainless steel plates, etc. According to the performance characteristics and uses of the steel plates, they can be classified into nitric acid-resistant stainless steel plates, sulfuric acid-resistant stainless steel plates, pitting-resistant stainless steel plates, stress corrosion-resistant stainless steel plates, high-strength stainless steel plates, etc. According to the functional characteristics of the steel plates, they can be classified into low-temperature stainless steel plates, non-magnetic stainless steel plates, free-machining stainless steel plates, and superplastic stainless steel plates, etc. The commonly used classification method now is based on the microstructure characteristics and chemical composition characteristics of the steel plates, or a combination of both. Generally, they are classified into martensitic stainless steel plates, ferritic stainless steel plates, austenitic stainless steel plates, duplex stainless steel plates, and precipitation-hardened stainless steel plates, or into two major categories: chromium stainless steel plates and nickel stainless steel plates. They have a wide range of applications, with typical uses including equipment for the pulp and paper industry, heat exchangers, mechanical equipment, dyeing equipment, film processing equipment, pipelines, and exterior materials for buildings in coastal areas, etc. Stainless steel plates have a smooth surface, high plasticity, toughness, and mechanical strength, and are resistant to corrosion by acidic and alkaline gases, solutions, and other media. It is an alloy steel that is not prone to rust, but it is not absolutely rust-proof.