Stainless steel gas pipe

Inquiry Form

Description

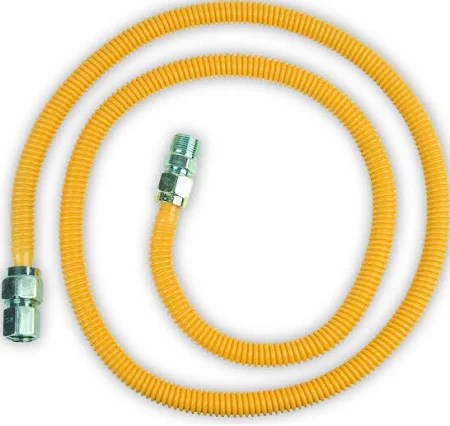

Product Name: Stainless Steel Gas Pipe

Product Overview

Stainless steel gas pipes, as the core components of modern gas transmission systems, have become the preferred choice for household, commercial and industrial gas facilities due to their outstanding corrosion resistance, high strength and long service life. The following is a systematic analysis from five dimensions: material properties, performance advantages, application scenarios, standard norms, and usage precautions:

I. Material Properties: Chemical stability of 304/316 stainless steel

Stainless steel gas pipes are made of 304 or 316 stainless steel as the base material. By adding elements such as chromium (Cr), nickel (Ni), and molybdenum (Mo), a dense oxide film is formed, effectively resisting corrosion from sulfides, chlorides in the gas and humid environments. For example:

304 stainless steel: Containing 18% chromium and 8% nickel, suitable for general gas environments;

316 stainless steel: With an additional 2% to 3% molybdenum added, it has stronger resistance to pitting and crevice corrosion and is suitable for coastal or high-humidity areas.

Ii. Performance Advantages: Dual guarantees of safety and economy

Corrosion resistance

The oxide film on the surface of stainless steel can prevent corrosive substances in gas from penetrating, and its service life can last up to 50 to 70 years, far exceeding that of galvanized steel pipes (10 to 15 years) and aluminum-plastic composite pipes (20 to 30 years). For instance, since Sichuan Gas Company promoted stainless steel gas pipes in 2005, the pipeline maintenance rate has dropped by 80%.

Impact resistance and seismic resistance

The elongation at break is ≥500%, which can withstand the deformation of pipelines caused by foundation settlement or earthquakes without cracking. The low-temperature embrittlement temperature is as low as -60℃, and no additional insulation measures are required for winter construction.

Sealing performance and leakage prevention

It adopts double compression or ring compression connection technology, achieving permanent sealing through metal deformation, with a leakage rate of less than 0.001%. Compared with rubber sealing rings, it avoids the risk of leakage caused by aging.

“Economy”

Although the initial cost is 30% to 50% higher than that of galvanized steel pipes, the total life cycle cost (including installation, maintenance and replacement) can be reduced by 40% to 60%.

Application fields

Household gas system

Connect the gas meter to the stove and water heater, replacing the traditional rubber hose (with a lifespan of only 1-2 years).

Commercial facilities

The gas pipelines for restaurants and hotel kitchens have remarkable high-temperature resistance and oil stain resistance.

Industrial field

High-pressure gas transmission for chemical plants, gas-fired power stations, etc., with a pressure resistance capacity of over 1.6MPa.

Technical specifications

Material: 304 304L 316L; 309S; 310S; 321; 409; 430; 443; 443; 446; 445J1/445J2; 2205; 2507, etc.

Customized according to the drawings

Packaging content

Export wooden crates or export cartons

After-sales service

The shelf life is 12 months from the date of receipt

Additional information

| Weight | 500 kg |

|---|