Summary of Stainless Steel Pipe Types and Applications

I. Stainless Steel Decorative Tubes

- Materials: 201 and 304 are the main materials, with a small amount of 301 and 316.

- Applications: Mainly used in staircase, window and door railings, and other decoration projects. Some products with lower requirements are used for piping.

- Features: Bright surface, brushed or frosted, with negative tolerance.

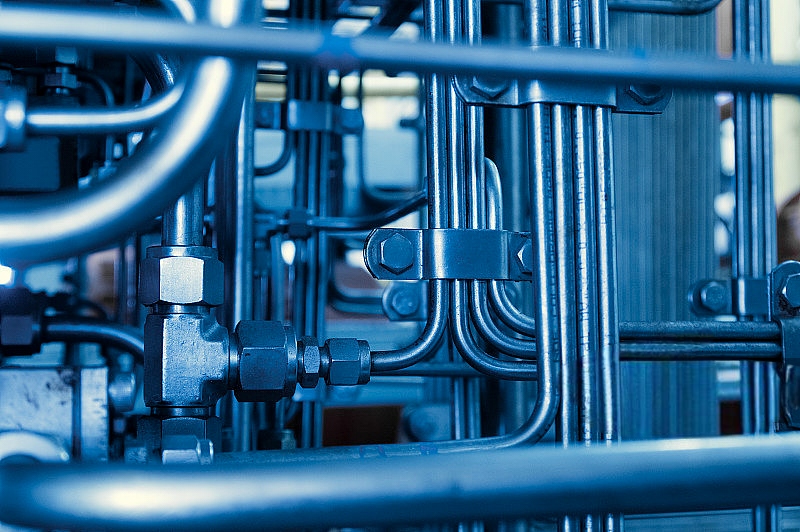

II. Stainless Steel Product Tubes - Materials: 201, 304, and 316 are the main materials.

- Applications: Used in bathroom and home decoration, product piping, fluid pipes, etc.

- Features: Strict requirements for positive and negative tolerance, surface brightness, and workmanship. May require bending, expansion, and contraction.

III. Stainless Steel Special-shaped Tubes

Special-shaped tubes are generally formed by secondary pressing of round tubes when the quantity is small (except for channel tubes). For larger quantities, they can be custom-made. Due to different specifications, molds may be lacking at times, and the corresponding mold costs may need to be borne. - Elliptical tubes: Regular elliptical tubes, flat elliptical tubes.

- Channel tubes: Round tubes, square tubes, rectangular tubes, elliptical tubes, etc. can all be slotted, commonly used for glass clamping in guardrail frames.

- Others: Triangular, handrails, arched, fan-shaped, door frame tubes, etc.

IV. Stainless Steel Patterned Tubes

The appearance of patterned tubes has changed the single appearance of traditional stainless steel tubes, refreshing people’s eyes. Currently, many tube factories have launched patterned tube projects. - Ordinary embossing: Traditional round tubes are embossed with gourd patterns in sections.

- European embossing: Patterns such as swastikas, auspicious clouds, and money are embossed on the surface of the tubes.

- Threaded tubes:

V. Colored Stainless Steel Tubes

A layer of color is electroplated on the surface of stainless steel tubes. Any material and specification can be used. The processing cost is increased according to the square meter on the basis of the tube. In the past, color plating was only available for tubes under 4 meters. Now, gold, rose gold, and black titanium can be color-plated for tubes up to 6 meters. Colored tubes require a reduction in welding probability and the use of connection pieces.