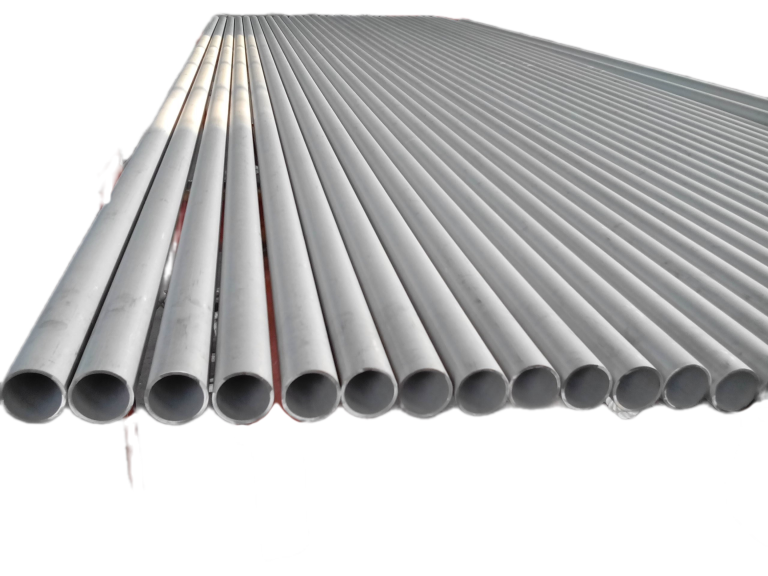

There are actually so many quality requirements for seamless steel pipes? !

① Chemical composition of steel: The chemical composition of steel is one of the most significant factors influencing the performance of seamless steel pipes, and it is also the main basis for determining the process parameters of tube rolling and the heat treatment parameters of steel pipes.

a. Alloy elements: Intentionally added, depending on the application. b. Residual elements: Introduced during steelmaking, appropriately controlled. c. Harmful elements: Strictly controlled (As, Sn, Sb, Bi, Pb), gases (N, H, O). Furnace refining or electroslag remelting: Improve the uniformity of the chemical composition in the steel and the purity of the steel, reduce non-metallic inclusions in the tube billet and improve their distribution morphology.

② Geometric dimensions and shape accuracy of steel pipes

a. Outer diameter accuracy: Dependent on the method of setting (reducing) the diameter, equipment operation conditions, process system, etc. The allowable deviation of outer diameter δ = (D – Di) / Di × 99.99% D: Larger or smaller outer diameter mm

b. Wall thickness accuracy: Related to the heating quality of the tube billet, the process design parameters and adjustment parameters of each deformation process, tool quality and its lubrication quality, etc. The allowable deviation of wall thickness: ρ = (S – Si) / Si × 99.99% S: Larger or smaller wall thickness on the cross-section

C. Ellipticity of steel pipes: Indicates the degree of non-roundness of the steel pipes.

d. Length of steel pipes: Normal length, set (multiplied) length, allowable deviation of length e. Bending degree of steel pipes: Indicates the bending degree of the steel pipes: Bending degree per meter of steel pipe length, bending degree of the entire length of the steel pipe

f. Skewness of steel pipe end faces: Indicates the inclination degree of the steel pipe end faces to the cross-section of the steel pipe g. Angle of steel pipe end face groove and blunt edge

- Surface quality of steel pipes: Surface smoothness requirements

a. Hazardous defects: Cracks, internal folding, external folding, crushing, delamination, scars, indentation, bulges, etc. b. General defects: Scabs, green lines, scratches, impacts, minor internal and external straight lines, roller marks, etc. Reason for occurrence:

① Caused by surface or internal defects of the pipe billet.

② Generated during the production process, such as incorrect design of rolling process parameters, roughness of the mold surface, poor lubrication conditions, and unreasonable design and adjustment of the die pattern.

③ If during the heating, rolling, heat treatment, and straightening processes of the pipe billet (steel pipe), excessive residual stress is generated due to improper temperature control during heating, uneven deformation, unreasonable heating and cooling speed, or excessive straightening deformation, then it is also possible for the steel pipe to develop surface cracks. - Steel mechanical properties: room temperature mechanical properties, high-temperature mechanical properties, low-temperature properties, corrosion resistance properties. The physical and chemical properties of the steel pipe mainly depend on the chemical composition of the steel, the microstructure, the purity of the steel, and the heat treatment method of the steel pipe.

- Steel pipe process performance: flattening, expansion, beading, bending, welding, etc.

- Steel pipe metallographic structure: low-magnification structure (macroscopic), high-magnification structure (microscopic) M, B, P, F, A, S

- Special requirements for steel pipes: contract attachments, technical agreements. keyword: Seamless Steel Pipe